- Home

- Products

- Vibrating Screen Panels

- Polyurethane Screens

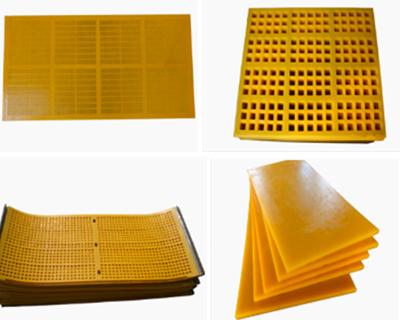

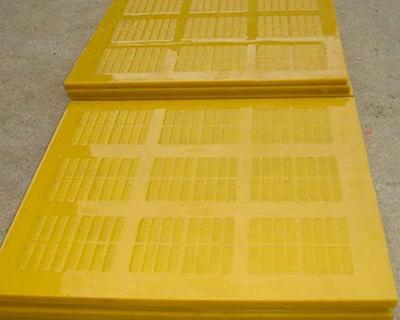

Polyurethane Screens

Left and right sided metal hooked edges are connected with steel wires by bolts to form a base skeleton, then it is covered by the polyurethane elastomers to produce the polyurethane screens. The diameter of the hole on PU screen is 0.08-180mm.

The PU screen panels has combined the high strength of the plastic and the high resilience of the rubber.

- Wide hardness range. Polyurethane still has the elongation and resilience of rubber under high hardness. Its Shore hardness range is A10-D80.

- High strength. Under rubber hardness, its breaking strength and bearing capacity is much higher than rubber. Under high hardness, its impact strength and resilience are much higher than plastic.

- Excellent Abrasion resistance. Under 0.01-0.10(cm3)/1.61km condition, its abrasion resistance is 3~5 times of that of rubber.

- Oil-resistant. polyurethane elastomer is a kind of strong polar macromolecular compound, which has little affinity for non-polar mineral oil and is almost free from corrosion in fuel oil and mechanical oil.

- Oxygen and ozone resistant.

- Good impact absorbing performance. PU can replace rubber or spring in die manufacturing industry for vibration attenuation and buffering.

- Polyurethane screens feature good cryogenic properties.

- Radiation resistant. PU is resistant to HER and performs satisfactorily under 10-10 Gy (?) radiation.

- The vibrating screen panels feature good machining properties (Lathing, milling, grinding and drilling).

The screen warp and weft wires are made by highly abrasion-resistant PU materials with steel wire set inside. Compared to the conventional metal screens, the service life of the PU screens has increased to 3~10 times. Its high resilience and plasticity reduce the blinding problems. The second harmonics high-frequency vibration of the screen panels decreases plugging conditions. The large opening area increases screening efficiency. The tensioned hooks are set in two sides of PU screen. The polyurethane vibrating panels also feature light weight, high flexibility, easy transportation and installation. The polyurethane screens can effectively absorb the impacts to reduce noise and improve the working environment.

Ore washing, screening, separation for metallurgy (iron ore, limestone, fluorite, cooling blast furnace slag, coke and other raw materials), ferrous and non-ferrous metal, coal, chemical, building materials, water-power engineering projects, abrasive materials treatment and quarry. New-structure PU screens with a variety of width and mesh diameter are available in Duratech. Ideal for applications in high impact/abrasion.

Skeleton screen panel, tensioned polyurethane screen panel, rectangular hole tensioned polyurethane screen panel, square hole screen, big hole screen, small hole screen, polyurethane woven screen, slatted screen panel.

- E-mail: osales@yeah.net

- Mobile: +86-15396721070 (Hot Line)

- Tel.: +86-515-98894585