Lining and Liner

-

- Rubber Lining The raw materials are imported, such as butyl rubber (USA EXXON MOBIL 1066, Japan JSR 268), natural rubber (Vietnam SVR 3L), chloroprene rubber (Japan DENKA M40).

-

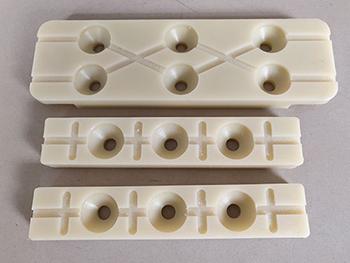

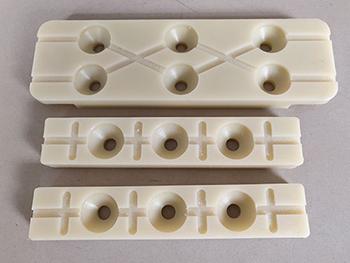

- Nylon Lining Polymerized quickly at a lower temperature, the nylon lining features high degree of crystallinity, good dimensional stability, low water absorption, high mechanical strength, high hardness ...

-

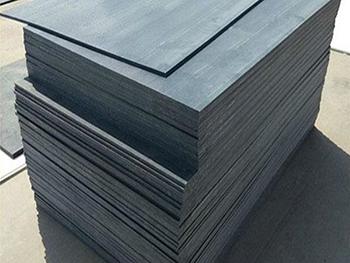

- PE Lining The PE lining is widely used in coal silo, stock bin, plaster silo, lime silo, cement silo, dump truck and mixing barrel of the steel, electricity, cement, coal and mining industry to solve the existed problems ...

-

- HDPE Lining The UHMWPE liner features high abrasion, corrosion, impact resistance, anti-sticking and self-lubrication and is widely used as the lining of storage silo, barrel, hopper or trough of the coal, cement, lime, mineral powder, and other powdery materials.

-

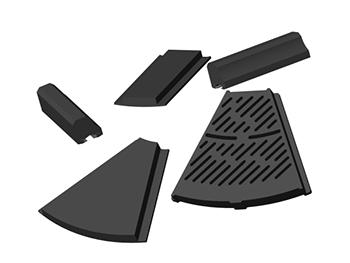

- Ball Mill Rubber Liner The ball mill rubber liner is widely used for metallurgy, mining, chemical, construction and electricity industries. Duratech can provide customers with ball mill liners with guaranteed quality, which is extensively applicable and energy saved.

-

- Autogenous Mill Rubber Liner The autogenous mill rubber liner is often used in the shell or ends of the ball mill. The ball mill lining consists of side shell liner, side shell lifter, center rubber circle, filler, shell lifter bar, shell liner, manhole plate and fastener.

-

- Rod Mill Rubber Liner A suitable rod mill rubber liner can be mounted to crush the materials and perform coarse grinding, which is the best replacement of the conventional manganese steel liner.

-

- Damp Mill Rubber Liner The damp mill rubber line is suitable for damp mills with peripheral discharge, a best replacement to the conventional manganese steel liner. The damp mill rubber liner features excellent ...

-

- Horizontal Tube Mill Rubber Liner The horizontal tube mill rubber liner performs excellently in fine grinding and it also features high abrasion resistance if using appropriately.

-

- Ceramic Liner The ceramic liner is sintered by AL2O3 (as main material) and other auxiliary materials through the 1700°C-high-temperature. The ceramic liner is widely used in coal conveyor, feeding system ...

-

- Ball Mill Ceramic Liner Duratech ball mill ceramic liner adopts international top-ranking materials and processing technologies and achieves the world-leading quality. Our ball mill ceramic liners have been sold to Europe, America...

-

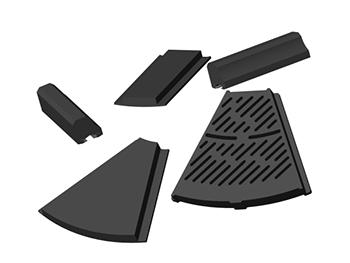

- Rubber Ceramic Liner The rubber ceramic liner consists of ceramic and rubber layer. The small-square ceramics are embedded into the specialty rubber backing mat to form a square abrasion-resistant rubber liner.