- Home

- Products

- Conveyor Belting

- EP Conveyor Belt

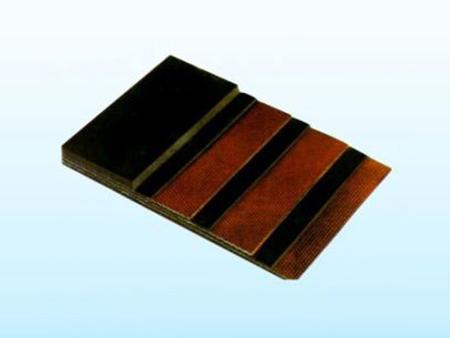

EP Conveyor Belt

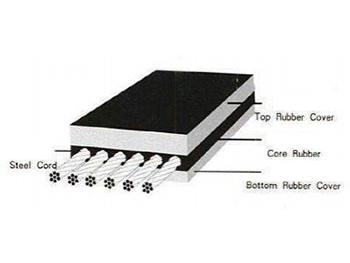

The general EP conveyor belt is suitable for conveying high-density bulk materials like ores and coals which will cause large impact and serious abrasion. The EP fabric conveyor is ideal for applications that need conveyor belt with high dimensional stability. However, the nylon conveyor belt is not suitable for the transportation of heated or greasy goods.

Features

- The EP (polyester) fiber features high elasticity modulus, low shrinkage and excellent dimensional stability. The elongation of the belt is so tiny that the conveyor belt can start and work steadily, which makes the EP conveyor belt ideal for both short-and long-distance conveyance.

- The EP conveyor belt is highly resistant against water and water vapor.

- Excellent adhesion properties to avoid layering and extend service life.

- Good troughability.

- The EP conveyor belt is highly resistant against impact.

- Good corrosion resistance.

- Good abrasion resistance.

- Longer service life to cut down the production cost and guarantee the production continuity.

Parameters

| Model | EP-100 | EP-150 | EP-200 | EP-250 | EP-300 | EP-400 | |

| Fabric thickness (mm) | 1.10 | 1.15 | 1.20 | 1.30 | 1.40 | 1.50 | |

| Longitudinal tensile strength (KN/m) | 3 layers ply | 300 | 450 | 600 | 750 | 900 | 1200 |

| 4 layers ply | 400 | 600 | 800 | 1000 | 1200 | 1600 | |

| 5 layers ply | 500 | 750 | 1000 | 1250 | 1500 | 2000 | |

| 6 layers ply | 600 | 900 | 1200 | 1500 | 1800 | 2400 | |

| 7 layers ply | 700 | 1050 | 1400 | 1750 | 2100 | 2800 | |

| 8 layers ply | 800 | 1200 | 1600 | 2000 | 2400 | 3200 | |

| Adhesive force (N/mm) | ≥8.0 | ||||||

| Reference elongation (%) | ≤1.2% | ||||||

| Abrasion (mm3) | ≤175 | ||||||

| Max. roll length (m/roll) | 300 | ||||||

High Temperature EP Conveyor Belt

The high temperature EP conveyor belt is appropriate for occasions where general heat resistant conveyor belts are being used. This kind of EP conveyor belt is mainly used for the transportation of sintering ore, coke, cement clinker and etc. in high temperature working environments, especially ideal for metallurgy and construction industry.

Features

- EP conveyor belt is suitable for conveying materials ≤125℃.

- Materials of special structure adopted and made by special processing technologies. High strength and good dimensional stability, suitable for applications need wide width and large conveying capacity.

- Good abrasion resistance, ideal for big lump sintering ores.

- Good troughability and steady conveyance.

- The base belt features high strength and can be clamped to another section of belt.

- Longer service life, as twice as that of the general heat resistant conveyor belt.

- High adhesion properties between different layer plies to avoid delamination.

Parameters (take EP200 as an example)

| Item | High temperature Ep200 conveyor belt | 100% cotton general high temperature conveyor belt | |

| Longitudinal tensile strength (≥KN/m) | 3 layers ply | 600 | 150 |

| 4 layers ply | 800 | 200 | |

| 5 layers ply | 1000 | 250 | |

| 6 layers ply | 1200 | 300 | |

| Reference elongation(%) | ≤1.5% | ≤3% | |

| Cover rubber tensile strength (MPa) | ≥16 | ≥12 | |

| Abrasion (mm³) | ≤150 | ≤180 | |

| Adhesive force (N/mm) | ≥12 | ≥4.5 | |

Send an Inquiry

Other Products

- E-mail: osales@yeah.net

- Mobile: +86-15396721070 (Hot Line)

- Tel.: +86-515-98894585