- Home

- Products

- Lining and Liner

- Rubber Lining

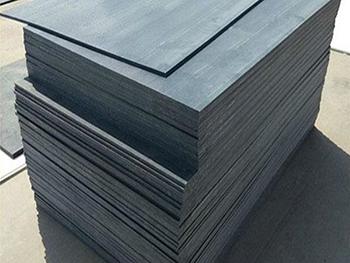

Rubber Lining

The raw materials are imported, such as butyl rubber (USA EXXON MOBIL 1066, Japan JSR 268), natural rubber (Vietnam SVR 3L), chloroprene rubber (Japan DENKA M40). According to differences of compounds, the rubber lining has the following types: HNR, SNR, IIR and CR. According to the vulcanization methods, the rubber lining can be divided into press vulcanization, atmospheric pressure vulcanization and prevulcanization type. Seawater resistant, sodium hypochlorite resistant or low calcium and magnesium specialty rubber linings are also available.

| Type | Model | Color | Physical properties | Working pressure MPa | Max. working temperature ℃ | Vulcanization pattern | Applications | |||

| Hardness Hs | Tensile strength Mpa | Elongation (%) | Metal binding force | |||||||

| IIR KI | KI -5 | Black | A57±7 | ﹥5.88 | >300 | >6kg/cm | ≧-0.098 | 100 | Press vulcanization | standard type, resistant to sulfuric acid and fluoric acid |

| KI-15 | Black | A62±7 | ﹥5.88 | 300 | >6kg/cm | Vulcanization at atmospheric pressure | On-site lining, other features are as same as the KI-5 | |||

| KI -7 | Black | A57±7 | ﹥5.88 | 300 | >6kg/cm | Press vulcanization | NaClO resistant, black rubber | |||

| KI-17 | Black | A62±7 | ﹥5.88 | 300 | >6kg/cm | Vulcanization at atmospheric pressure | On-site lining, other features are as same as the KI-7 | |||

| KI-5S | Black | A52±7 | ﹥3.92 | >300 | >6kg/cm | Pre-vulcanized | Steam vulcanization is not needed. Applicable to on-site lining without steam. | |||

| HNR KH | KH-5 | Black | D80±10 | ﹥29.00 | 15-50 | 80kg/cm2 | ≧-0.098 | 100-120 | Press vulcanization | Corrosion-resistant under high-temperature (mercury electrolytic device, water treatment device, HCI, CI, alcohol recycling device) |

| KH-7 | Black | D75±10 | ﹥19.60 | >10 | 80kg/cm2 | 85 | Press vulcanization | Standard type, acid resistant (hydrochloric acid, dilute sulfuric acid), base resistant, saline solution resistant, highly flexible and impact resistant | ||

| KH-7I | Black | D75±10 | ﹥19.60 | 30-60 | 80kg/cm2 | Press vulcanization | Standard type, HNR, low Ca and Mg ion content. Applicable to vessels and pipelines with ionic membrane caustic soda units | |||

| KH-8 | Black | D80±10 | ﹥19.60 | 30-60 | 80kg/cm2 | Press vulcanization | Specially designed for fluorine proof | |||

| KH-15 | Black | D70±10 | ﹥14.70 | >5 | 40kg/cm2 | Vulcanization at atmospheric pressure | On-site lining, light organic solvent resistant, SO resistant | |||

| KH-16 | Black | D70±10 | ﹥14.70 | 1-30 | 40kg/cm2 | 85 | Vulcanization at atmospheric pressure | Laminating on SNR as the interlining. On-site lining | ||

| KH-20 | Black | D75±10 | ﹥14.70 | 1-30 | 40kg/cm2 | Vulcanization at atmospheric pressure | Low Ca and Mg ion content. Applicable to vessels and pipelines with ionic membrane caustic soda units. On-site lining. | |||

| 8501 | Black | D80±10 | ﹥14.70 | ﹥10 | 60kg/cm2 | Press vulcanization | Hard rubber, water treatment devices | |||

| Semi-hard rubber | 8502 | Black | D60±10 | ﹥10 | ≧30 | ≧6.0 | ≧0.98 | 85 | Press vulcanization | Standard half hard rubber, applicable to nuclear and thermal power plants and water treatment devices. |

| SNR KR | KR-4 | Black | D42±7 | ﹥15.7 | >500 | >6kg/cm | ≧-0.098 | 85 | Press vulcanization | Abrasion resistant to granules |

Send an Inquiry

Other Products

- E-mail: osales@yeah.net

- Mobile: +86-15396721070 (Hot Line)

- Tel.: +86-515-98894585