- Home

- Products

- Lining and Liner

- Nylon Lining

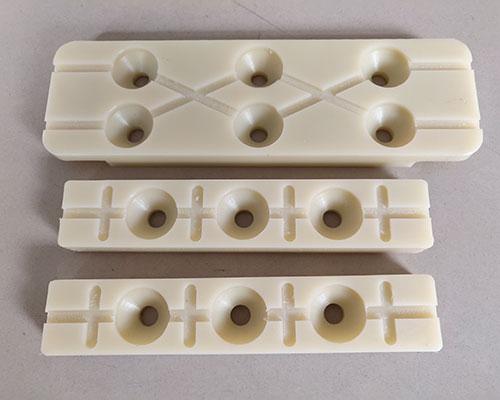

Nylon Lining

Duratech nylon lining is modified based on the MC nylon. Polymerized quickly at a lower temperature, the nylon lining features high degree of crystallinity, good dimensional stability, low water absorption, high mechanical strength, high hardness and superior heat resistance.

- Light weight as 1/7 as the weight of manganese steel lining board. Heavily reduce the weight of the vessel.

- Low noise. The noise decreases by 10-15 db in the mechanical devices, storage hopper, barrel and tank where the nylon lining is adopted.

- Good mechanical properties. This Nylon is crystallized below its melting point and has a large molecular weight which leads to higher mechanical strengths than nylon 6 and nylon 66. Duratech nylon lining also features high resistances to creep and fatigue, which allows for bearing heavy load for quite a long time without deformation.

- Good resilience. The nylon lining can prevent the curved face from deformation and keep the strong toughness to prevent fracture caused by repeated impact loading, which is necessary for products to bear high impact load.

- Excellent abrasion resistance and self-lubrication. The nylon lining generally doesn't need extra lubricant under light load or at low speed.

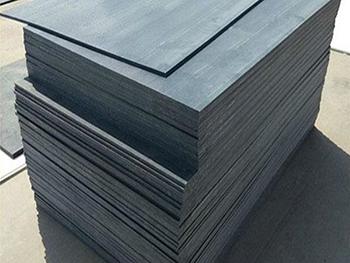

The oil-filled nylon features 3~6 million molecular weight (density>0.940 g/m3) while the high-density PE resin only has 0.3~0.5 million. This difference guarantees the enough strength of the HDPE to achieve superior abrasion and impact resistance that another low-grade polymer can't achieve. That's why HDPE is the best engineering plastics with corrosion resistance and self-lubrication.

Lining of metallurgy barrel, storage tank, trough, hopper, sintering machine, transporter. Various specifications are available.

- Excellent abrasion resistance to extend the service life.

- Light weight and easy installation.

- Superior self-lubrication and anti-sticking.

- The oil-filled nylon lining is chemical corrosion resistant.

- E-mail: osales@yeah.net

- Mobile: +86-15396721070 (Hot Line)

- Tel.: +86-515-98894585