- Home

- Products

- Lining and Liner

- Ceramic Liner

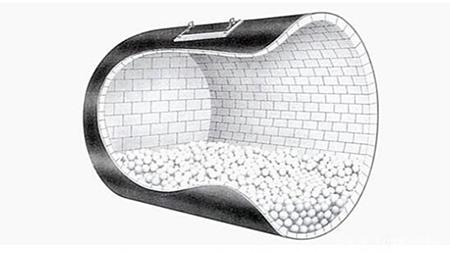

Ceramic Liner

The ceramic liner is sintered by AL2O3 (as main material) and other auxiliary materials through the 1700°C-high-temperature. The ceramic liner is widely used in coal conveyor, feeding system, coal pulverizing system, ash discharge system, dust removal system and other high-abrasion mechanical equipment of thermal power, steel, metallurgy, mechanical, coal, mining, chemical, cement, port and other industries. Duratech offers a wide variety of ceramic liners to allow customers to choose the best fit liner according to their own production needs.

High hardness. The hardness of the ceramic liner is second only to diamond and tits abrasion resistance far exceeds that of wear-resistant steel and stainless steel.

Excellent wear resistance. 266 times as that of the manganese steel and 171.5 times as that of the high-chromium iron. According to our customer follow-up survey in decades, the ceramic liner can extend the equipment service life to more than ten times.

Light weight. Density of 3.6g/cm3 is only half of that of the steel, greatly reducing the equipment load.

The ceramic liner is ideal for coal conveyor, feeding system, coal pulverizing system, ash discharge system, dust removal system and other high-abrasion mechanical equipment of thermal power, steel, metallurgy, mechanical, coal, mining, chemical, cement, port and other industries. Customers can choose the best fit ceramic liner according to their needs.

- Al2O3 ≥92%

- Density ≥3.6 g/cm3

- Rockwell hardness ≥85 HRA

- Compressive strength ≥850 Mpa

- Breaking tenacity(KΙC) ≥4.8 MPa·m1/2

- Flexural strength ≥290 MPa

- Thermal conductivity coefficient: 20 W/m.K

- Coefficient of thermal expansion: 7.2×10-6m/m.K

- E-mail: osales@yeah.net

- Mobile: +86-15396721070 (Hot Line)

- Tel.: +86-515-98894585